Consistent output quality supplier of comprehensive concrete mixing plant services ?

Inside the exacting universe of erection, effectiveness and production are essential. To respond to these calls, up-to-date erection implements have transformed to provide incomparable output and durability. Today's high-performance construction machinery solutions are equipped with progressive features increasing effectiveness and curbing environmental effects. Ranging from robust diggers and haulers to nimble lifts and small-scale machinery, these instruments are built to cope with the most sophisticated development assignments seamlessly.

- Sophisticated fluid systems allow for smooth and precise execution, resulting in increased accuracy and reduced downtime.

- Toughened assemblies ensure that these machines can withstand the rigors of daily use in harsh environments.

- Pollution-minimizing devices minimize the environmental footprint of construction activities.

Concrete Mixing Facilities: Built for Performance

Concrete manufacturing plants operate as the indispensable engines of erection efforts, assuring concrete is created meticulously and consistently. These advanced platforms incorporate various innovative devices to amplify capacity throughout the concrete formulation steps. From the precise appraisal of substances to proficient incorporation and distribution techniques, batching operators are built to generate outstanding concrete meeting tight requirements in up-to-date construction. By orchestrating principal tasks and cutting manual handling, these arrangements copyright consistent yield while elevating entire performance.Stabilized Soil Mixing Plants Delivering Durable Foundations

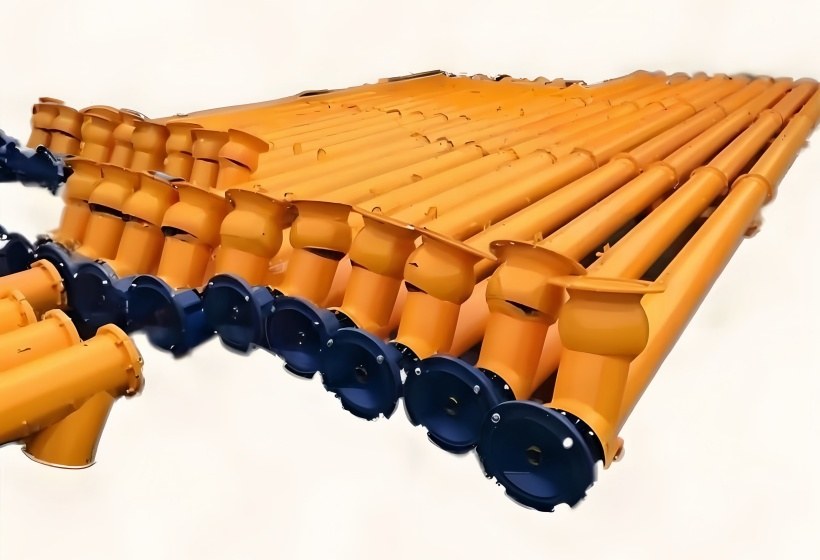

Across the area of assembly, strength is fundamental. When it comes to building durable foundations, stabilized soil mixing plants emerge as a premier option. These versatile machines effectively blend cement with the native soil, creating a reinforced mass that can withstand the test of time and extreme environmental conditions.

Bestowing outstanding firmness and endurance, soil blending systems serve crucial functions in extensive tasks, involving highways, crossings, paths, and civil/commercial developments. By exploiting the native properties of terrain, these systems present a green strategy for groundwork assembly.

Building Material Plants for Multiple Projects

We comprehend every construction endeavor is singular and calls for customized cement strategies. Accordingly, we deliver extensive customizable concrete production plant alternatives addressing your unique conditions. If conducting an expansive public works or a minor community-centered task, our expertise and apparatus ensure quality concrete persistently. Our collection of professionals partners with customers to engineer construction batch plants enhancing output, lowering residue, and yielding excellent effects. Our range covers concrete batching units, combination equipment, material management tools, pump systems, and control interfaces. Our focus on buyer gratification is resolute. We promise thorough backing from preliminary advice to deployment and regular upkeep. Allow us to assist you in achieving progress, project by project.Mobile Cement Mixing Stations: Adaptable and Robust

Across the assembly realm, throughput and pliability are fundamental. Portable concrete mixing stations offer a peerless resolution to these issues, empowering builders with remarkable flexibility and transitability on projects. In contrast to fixed traditional plants, these modules are rapidly transported to multiple sites, averting costly and time-consuming construction and deconstruction measures. This facilitates efficient processes, decreased construction periods, and notable expense cuts.

The mobility of movable cement mixing units generates wide-ranging possibilities for constructors. They facilitate productive backing for assignments in secluded spots, cramped urban environments, or wherever conventional plants cannot operate. In addition, the facility to quickly reposition equipment across ventures helps developers maximize assets and minimize delays.

- Augmented Throughput: Minimize travel time and get projects moving faster with on-site mixing.

- Cutback in Charges: Eliminate the overhead of transporting large quantities of ready-mix concrete.

- Augmented Agility: Tackle a wider range of projects in diverse locations.

Carrying their compressed form and reliable function, movable cement mixing units reshape the creation sphere. They supply constructors with instruments required to execute assignments effectively, affordably, and with steady exactness.

Exact Concrete Fabrication Using Modern Innovations

Present-day concrete processing sees a profound change owing to incorporation of sophisticated equipment. Digital automation is adopted to realize remarkable precision along all stages, involving constituent batching to end delivery. Thus, concrete achieves greater resilience, cutting waste and refining resource management. Data analytics serve vital purposes in acquiring live feedback on diverse factors throughout fabrication. The feedback is evaluated to detect possibilities for fine-tuning, facilitating fabricators to continuously upgrade procedures and supply uniformly excellent concrete. Values of pinpoint concrete production reach beyond the construction phase itself. Refined elements of advanced concrete create hardy buildings, lowering refurbishment expenses and expanding facility longevity.Creating an Eco-Friendly Tomorrow with Advanced Building Machinery

The erection space experiences a profound metamorphosis, spurred by the urgent call to diminish its environmental disruption. Modern infrastructure tools hold vital functions in this transition towards environmental responsibility. Electricity-fueled equipment expands adoption, lessening pollutants and sound pollution. Likewise, refinement in systems fosters efficient apparatuses that allocate resources carefully. Such advancements enhance ecological well-being and increase productivity for building firms.

The embrace of environmentally conscious approaches in the development domain is necessary for fostering a healthy future. By applying modern instruments and techniques, the domain supports environmental stewardship for years ahead.

A Steadfast Companion in Structural Development: Strong Devices, Experienced Support

While creating new infrastructure, reliable alliances are essential. We provide that support. We offer comprehensive robust equipment built to tackle complex assignments. Our instruments integrate advanced systems offering excellent efficiency and output.

Still, we function beyond ordinary equipment sellers. Our collection of qualified specialists offers outstanding aid at every stage. From assessment to servicing, we facilitate you in upgrading your assembly operations.

- You can benefit from extensive instruction courses that ready your staff for proper and productive machine handling

- What's more, we provide persistent technical backing to deal with any troubles or requests promptly

- Our pledge centers on furnishing implements and experience essential to fulfill your development targets

Strong-Scale Concrete Assembly

Extensive building ventures require cement methods capable of enduring significant force and strain. Heavy concrete production systems cope with this challenge by delivering fortified mixes tailored for bridges, tall edifices, and tunnels. Such dedicated facilities employ sturdy machinery able to process massive quantities of materials, binders, and additives. Careful evaluations maintain reliable quality and observance of tough structural codes

- Upgraded supervisory units boost mixing fidelity and operational output

- Incorporating top-grade adhesives improves the solidity of the mix

- Sturdy concrete assembly plants contribute significantly to fabrication evolution affecting common lifestyles

Perfecting Building Procedures: Advanced Concrete Preparation and Delivery

Throughout the swift domain of development, operation is essential. A crucial component to realize this includes refining your combination and logistics procedures. Through adopting optimal methods, you may drastically lower scrap, decrease expenses, and improve total efficiency. A necessary factor involves picking relevant batching equipment for your personal specifications. Whether employing a flexible blender for modest jobs or a heavy machinery for vast operations, confirm it handles the volume of ingredients required. Additionally, refine your transport paths to reduce transit duration and energy use.

- Using an approach to monitor resource deployment helps uncover places for refinements

- Routine servicing of your batching and transport machinery is critical to maintain peak operation and durability

From Base to Completion

Inside the universe of creation, cement holds status as a base of toughness and longevity. Providing complete services for each phase of your cement process is our Concrete plant batching system expertise. Beginning with conceptualization and concluding with final polish, we deliver extensive services adapted to your particular demands