long term custom fabricated tube sheet plates?

Each time elaborate extended tube planning and assembly, partnering with true adepts is critical. These trained profiled pipe production experts possess a intensive appreciation of heat distribution principles, element nature, and the cutting-edge methods for creating high-performance heat exchangers. They address everything from initial drafting and sample production to large-scale production and careful assessment. Selecting the right ribbed pipe assembly technician can considerably boost the performance and endurance of your device.

Innovative Textured Channels

Process factory systems frequently demand extremely efficient warmth diffusion, and enhanced finned sections are essential to achieving this. These segments include precisely designed edge geometries, often utilizing elaborate layouts to boost the stretch available for temperature distribution. Fabrication approaches may involve rolling, accompanied by accurate fin formation and sporadically a tailored surface application to more improve output. Adopting the right finned pipe composition is based on the certain working states, like gas features, heat levels, and compression readings.

Tailored Profiled Metal Tubing Options

Handling challenging heat-related management needs? Our dedicated team constructs purpose-built copper pipe systems precisely tailored to your application. We exploit advanced building techniques and specific calculations to optimize energy conduction efficiency. Whether you're in the mechanical sector, or need top-tier cooling regarding a demanding system, our heat-exchanged copper ducts can ensure improved effectiveness. We appraise factors such as substance conveyance rates, adjacent climatic factors, and geometric constraints to develop a truly bespoke and efficient answer.

Specialists in Aluminum Fin Tube Technology

For years, we've been dedicated to providing unparalleled expertise in profiled aluminum tubing design, construction, and setup. As leading authorities, we offer a comprehensive collection of services, catering to a diverse spectrum of industries, including heating and cooling, load supply, and chemical engineering. Our crew of certified engineers has a deep understanding of heat movement principles and fabric science, ensuring that every task we undertake delivers optimal output and durability. We pride ourselves on delivering specialized answers that precisely satisfy our clients’ unique requirements. Whether you require heat dissipator repair, restoration, or a comprehensive system layout, our determination to top-tier standards remains unwavering. Connect with us today to explore your definite difficulties.

Enhanced Tube Design and Guidance Solutions

Optimizing caloric conduction efficiency is paramount in countless applications, and that's where specialized upgraded tube fabrication and advisory provisions truly shine. We deliver comprehensive remedies encompassing everything from initial notion to full-scale implementation. Our workforce of experienced technicians leverage advanced projection techniques and domain best techniques to formulate customized improved tube assemblies for a wide array of complicated environments. Whether you're seeking to increase capability, minimize electricity costs, or resolve specific functional issues, our upgraded tube expertise ensures maximum results. We also offer frequent maintenance options to confirm durable effective integrity.

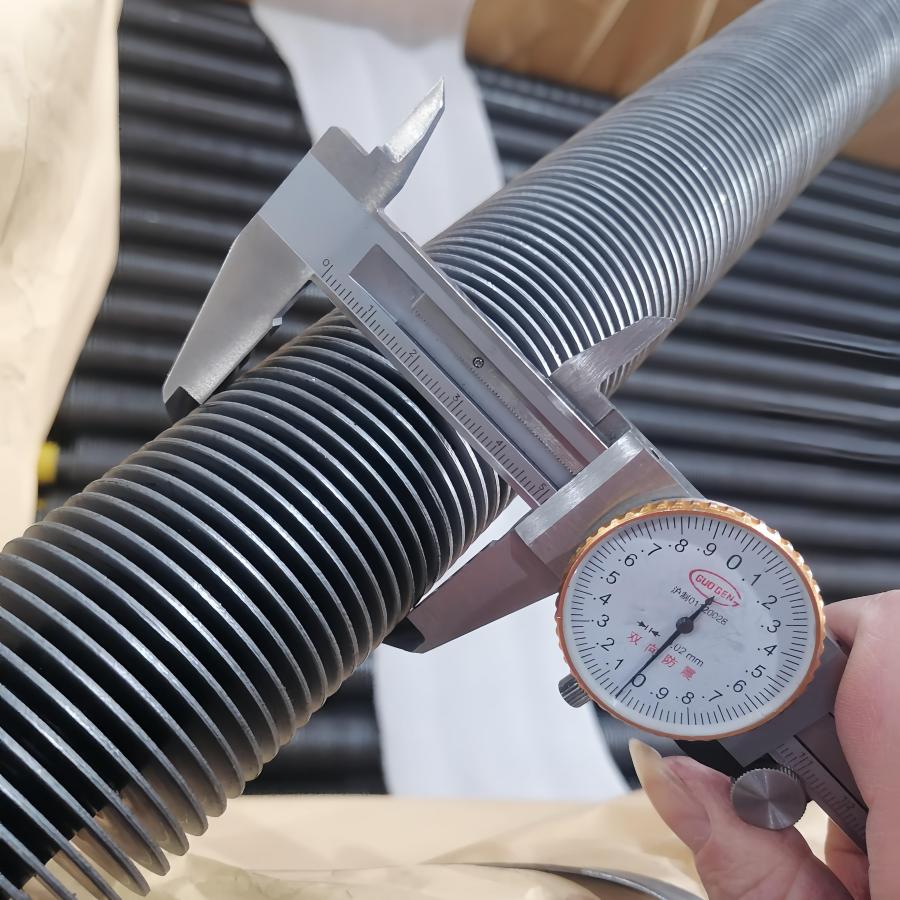

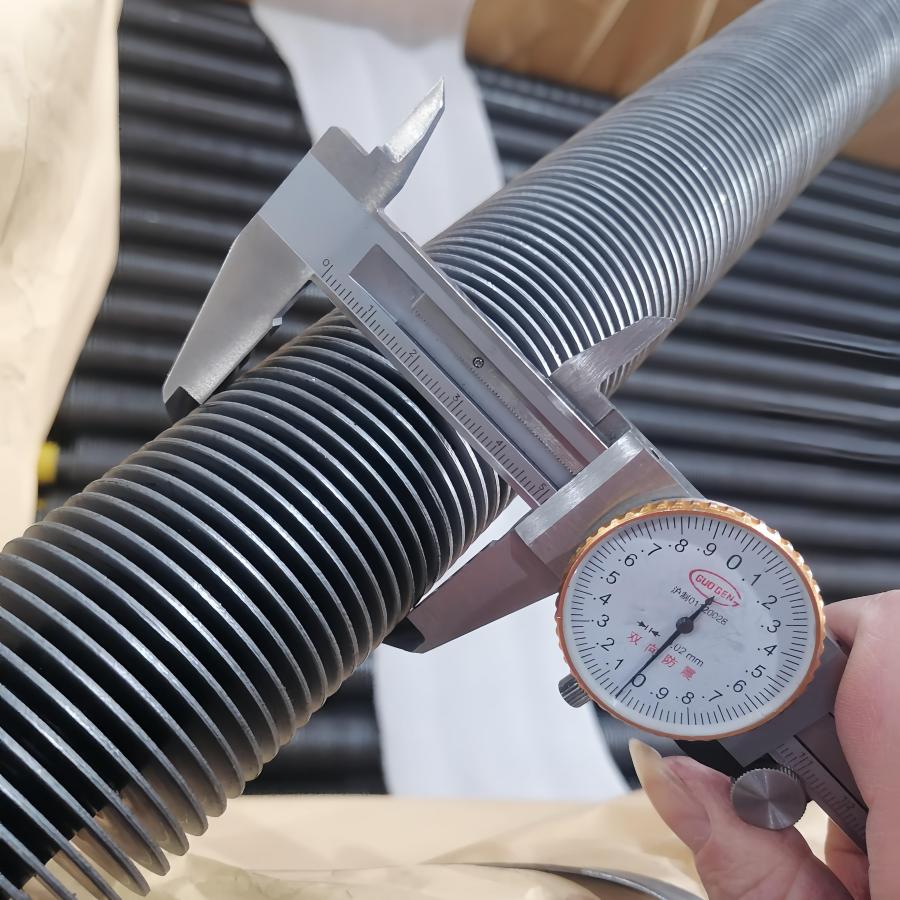

Cutting-Edge Precision Textured Tube Fabrication

The needs of modern heat migration systems are pushing a development towards highly specialized radiating tube fabrication. Traditionally, ordinary fin forms were acceptable, but now applications in technology and factory processing necessitate remarkably tight tolerances and complicated geometries. This involves faithful rolling of fins directly onto the tube shell, often utilizing innovative cold manufacturing equipment to secure the desired flange height, distance, and form. Over and above, the material selection plays a essential capacity, with dedicated fusions frequently utilized to boost thermal effectiveness while maintaining framework integrity. Standard assurance practices are also key to preserve stable finned tube grade.

Extended Copper Pipe for Heat Exchangers

Cutting-edge heat exchange systems frequently incorporate finned copper duct as a crucial part in heat exchangers. The integration of fins, ordinarily made from non-ferrous metal, significantly enlarges astm b171 the surface space available for heat diffusion, leading to a superior efficient heat movement. These augmented copper pipelines are generally found in applications ranging from factory processes, such as thermal management machinery, to family HVAC systems. The prime thermal heat transmission of copper, associated with the amplified surface region provided by the fins, generates in a extremely effective method for handling heat. Different fin configurations, including planar and wavy, provide varying degrees of performance optimization depending on the distinct application’s conditions.

Cutting-edge heat exchange systems frequently incorporate finned copper duct as a crucial part in heat exchangers. The integration of fins, ordinarily made from non-ferrous metal, significantly enlarges astm b171 the surface space available for heat diffusion, leading to a superior efficient heat movement. These augmented copper pipelines are generally found in applications ranging from factory processes, such as thermal management machinery, to family HVAC systems. The prime thermal heat transmission of copper, associated with the amplified surface region provided by the fins, generates in a extremely effective method for handling heat. Different fin configurations, including planar and wavy, provide varying degrees of performance optimization depending on the distinct application’s conditions.Aluminum Finned Tubes: Lightweight & Efficient

Aluminum textured tubes offer a compelling combination of slimline construction and remarkable productivity, making them ideal for a diverse range of commercial heat transfer processes. Their unique formation—featuring aluminum textures attached to the tube face—significantly boosts the heat exchange ability without adding substantial extent. This translates to lessened energy spending and improved overall operation reliability. Consequently, these tubes are frequently appointed in HVAC setups, refrigeration, and other heat dissipating processes where minimizing mass and maximizing power transfer are paramount points.

Finned Tube Material Options: Metallic Copper & Aluminium

While considering finned tube fabric, engineers frequently scrutinize copper and aluminum. Copper offers exceptional erosion endurance and superior caloric transfer, making it advantageous for applications where high-performance heat transfer is paramount, such as in climate control systems. However, copper's raised valuation and possible for galvanic corrosion with other components can be limiting constraints. Conversely, aluminum provides a significantly lower price and benefits from a lower density, which is advantageous in weight-sensitive designs. While aluminum's thermal conductivity is lower than copper's, it remains adequate for many applications, and surface treatments can often improve its performance. Ultimately, the best material selection hinges on a thorough analysis of the specific operating conditions, budget constraints, and required performance characteristics.

Improving Heat Exchange with Finned Conduits

The effectiveness of heat exchangers frequently hinges on the design and installation of finned conduits. These structures significantly boost the surface area available for heat movement, allowing for a much greater withdrawal of heat compared to simple, unfinned conduits. The boost process involves a complex interplay of factors, including fin configuration – such as fin magnitude, spacing, and size – as well as the fabric of both the fins and the root tubes themselves. Careful consideration of the gas flow characteristics, whether it's air or a liquid, is also paramount to ensure that the heat elimination isn’t restricted by boundary layer effects or uneven spread of the working mass. Ultimately, a well-designed finned conduit array delivers a substantial improvement in overall thermal capability within a given space.

Robust Finned Tube Setups for Industrial Applications

Fulfilling the call of demanding production environments necessitates hardy heat transfer systems. Our finned tube solutions are engineered for exceptional effectiveness, providing stable heat exchange in a range of applications, from power processing to temperature control control. Constructed from high-grade materials and featuring advanced wear endurance techniques, these elements minimize restoration downtime and maximize operational performance. The distinctive fin pattern promotes enhanced heat movement, even under tough operating situations.